93 805 42 42 - 93 802 24 09

What do we offer?

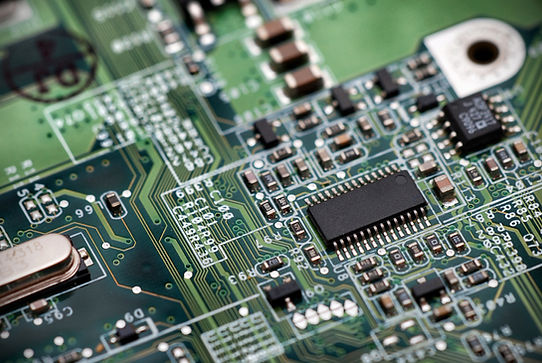

With the flexibility of managing your project with constant changes in the supply of materials, evolving designs, and changes in programs, your company will have our support from Subcoele to build its prototype on time.

In addition, we will collaborate on the synergies of its design to help reduce costs and

time, in order to ensure the correct manufacture of their products.

Subcoele works for the following sectors:

Lighting

Industrial

Renewable energies

Medical

Home automation

Teaching

01.

Prototypes .

02.

Small series .

03.

Great productions .

We have two complete production lines, compatible with each otherand that allow us to offer the flexibility you

need to produce both your prototypes, small series or large productions.

At Subcoele you will find at your disposal, among others, the following processes:

SCREEN PRINTERS

Automatic screen printers with self-monitoring frames Alpha- VectorGuard.

SPI 3D

Mirtec 3D SPI with online cloosed-loop system.

P & P

IPulse line of vision with great flexibility for small series.

P & P

FUJI NXT3 high speed chip shooter line.

REFURBISHMENT

BTU Piramax and Electovert Omniflow reflow ovens.

COATING

1 automatic coating line with 2 heads + Tilt axis.

AOI 3D

Mirtec 3D AOI online.

WAVE WELDING

Wave welding machine.

SELECTIVE WELDING

Selective welding of 3 modules.

REWORK

Hybrid Rework System with reprocessing and prototyping service.

DEHUMIDIFYING CABINET

EASY Dry Series dehumidifier cabinet with adjustable humidity range.

SCREEN CABINET

Smart screen store.

X - RAY INSPECTION SYSTEM

3D X-ray inspection system with tomography.

DEHUMIDIFYING CABINET

EASY Dry Series dehumidifier cabinet with adjustable humidity range.

SCREEN CABINET

Smart screen store.

ROBOTIC WAREHOUSE

X - RAY INSPECTION SYSTEM

3D X-ray inspection system with tomography.

Robotic warehouse 4.0 for SMD with traceability

level 3.

ROBOTIC WHAREHOUSE

KOLB CLEANING

Cleaning system that cleans screens, spatulas, solder carriers and misprints.

Equipment manufacturing

From the initial concept of your electronic equipment to its final delivery, we guarantee you the shortest time of

manufacturing, less uncertainty, and a reduction in

costs without going any further.

We make sure everything fits: we will assemble your plates

electronic and we will configure the box that will protect and accommodate all its elements.

We will integrate both hardware and software, and if necessary we will add functional tests and reliability analyzes

to make sure everything works properly.

01.

Reduced time.

02.

Cost reduction.

03.

Reliability analysis.

And warehouse assisted by other materials.

Our testing and verification services for the assembly of your electronic circuits can help you cut down on marketing time.

At Subcoele, we are ready to deliver your verified circuits, using optical inspection and functional electrical verification.